"Risk Based Thinking," a systemic approach to risk management, is an innovative method that can also be applied to Safety... and worker health. In our article "Beyond Compliance: Risk Based Thinking," we discussed the value it can bring to a company when implemented across all organizational levels and structured with an appropriate methodological framework.

The essential elements of Risk Based Thinking are based on identifying the company's operating context, including its processes and their correlation, using a consistent methodology and evaluation criteria throughout the organization, and fostering collaboration across all business functions to share individual know-how.

Defining the context for Health and Safety of workers involves mapping relevant health-safety processes, focusing on Risk Families and Areas, and subsequently identifying specific risks.

For illustrative purposes:

|

Risk Category |

Risk Area |

|

Operational Risks |

Health |

| Safety | |

| Organization |

For each of these Risk Areas:

- Health

This area encompasses risks related to exposure and contact with harmful agents, which can be chemical in nature (e.g., hazardous substances) or physical (e.g., sources of noise emission, vibrations, ultrasonic waves).

- Safety

The risks in this area pertain to events that could lead to workplace injuries caused by traumatic contact with tools, machinery, equipment, or mobile devices.

- Organization

This area includes risks associated with intrinsic work-related events, typically encompassing work relationships, interpersonal dynamics, and organizational aspects. For example, risks related to work-related stress, psycho-social risks.

Specific risks are mapped for each of these risk areas, such as:

|

Risk Area |

Specific risks |

|

Health |

Microclimate, severe hot/cold environments |

| Manual handling of loads – Lifting and carrying | |

| Manual handling of loads – Pushing and pulling | |

| Electromagnetic fields | |

| Electrocution | |

| Noise | |

| Whole-body mechanical vibrations | |

| Hand-arm mechanical vibrations | |

| Carcinogenic and mutagenic agents | |

| Biological agents | |

| Chemical agents, flammable/explosive materials, corrosive substances, unstable reactive substances | |

| Ionizing radiation | |

| Artificial optical radiation | |

| Video display terminal radiation | |

| Night work | |

|

Safety |

Crushing, shearing, cutting, entanglement, dragging, trapping, impact, puncture, friction or abrasion, contact with high/low temperatures, falls from height |

| Stumbling, slipping | |

| Collision, impact, crushing, friction/abrasion from contact/use with forklifts, pallet trucks, machinery, and moving vehicles | |

| Fire | |

| Explosion | |

| Falling objects | |

| Toppling of shelves, cabinets, equipment | |

| Falls from height in elevated work | |

|

Organization |

Work-related stress |

| Psycho-social risks | |

| Pregnant women/ Mothers in postpartum/ Breastfeeding period |

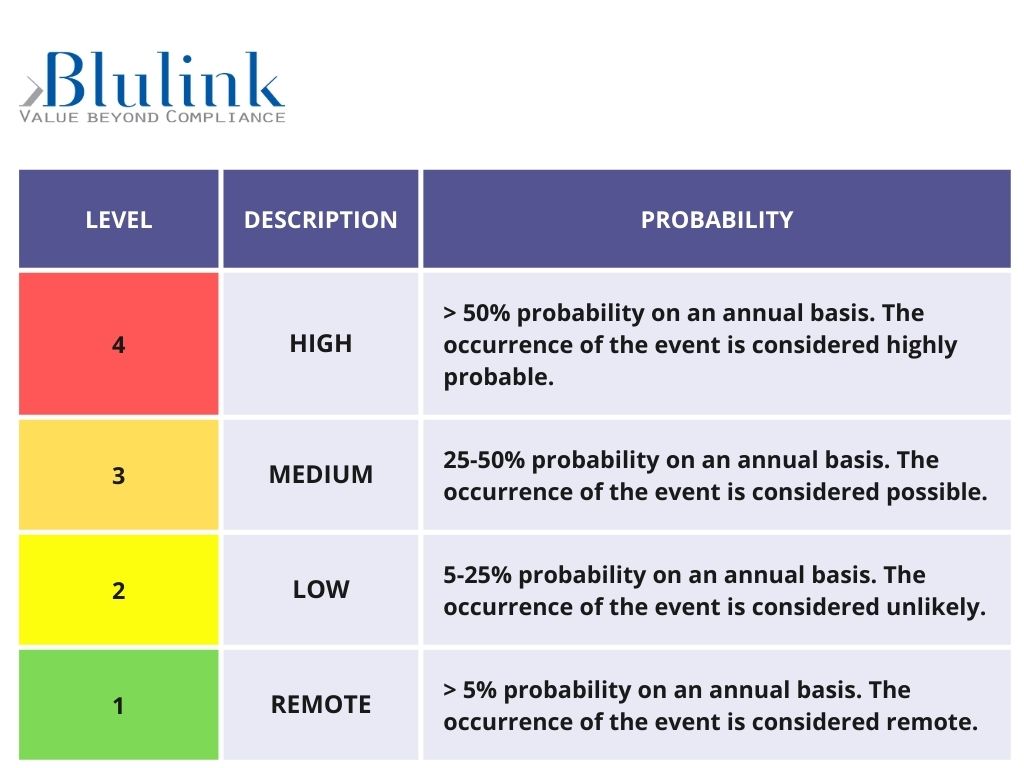

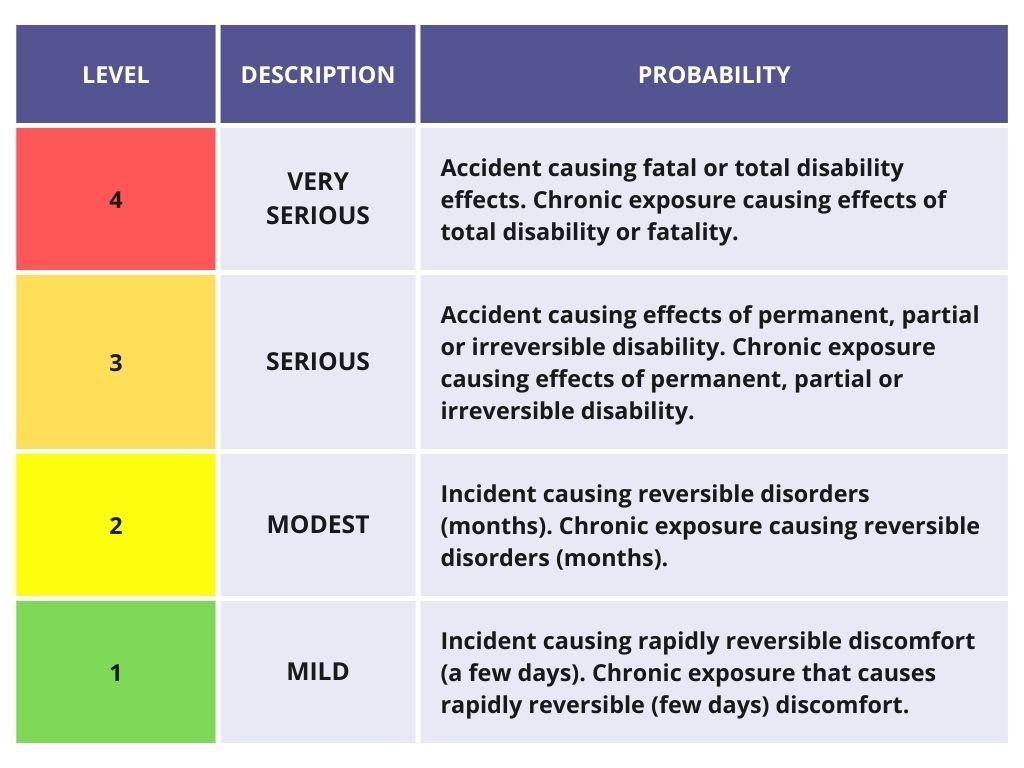

The next phase of the risk management process involves defining evaluation criteria that will be applied to the identified risks. Several criteria exist in literature and are applied based on the complexity of the required evaluation; these can be based on calculation algorithms, two-dimensional matrices, or instrumental measurements. As an example, we present the multi-level two-dimensional matrix criterion, where the matrix elements are the probability of the event occurring and the impact:

Probability: expressed as the % likelihood of the event occurring within a 1-year time horizon.

Impact: damage to the health and safety of the worker

Table 3 - Probability of Occurrence

Table 4 - Impact on Health and Safety (Damage)

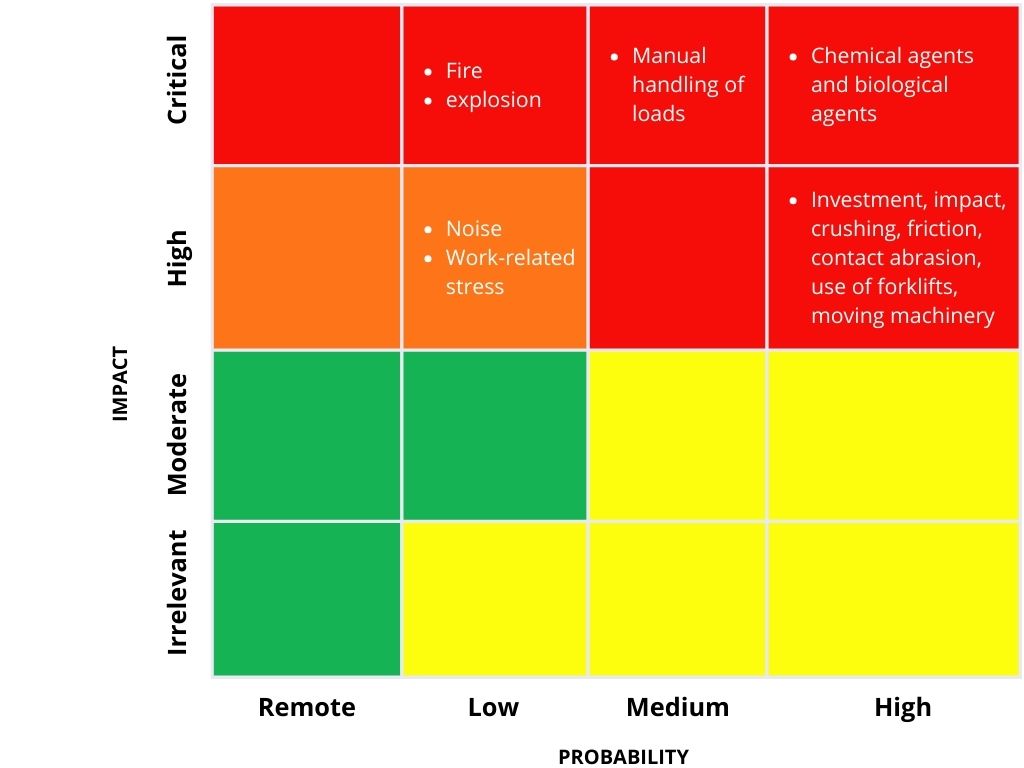

Having defined the risk assessment criteria, we proceed to evaluate R = P x I for the mapped risks, the overall result of which can be reproduced in a "heat map" (highlighting only those with R >= 6).

Fig. 2 – Heat Map

In the example provided, the risk assessment with its corresponding "heat map" highlighted significant risks to the health and safety of workers:

- in workplaces

- in the use of plants and equipment

- in contact with chemical agents

- in work methods

These are the areas where risk treatment and improvement plans should be directed. Additionally, attention should be given to the risks of noise and work-related stress, although they are less significant.

The application of "Risk Based Thinking" as a daily operational practice in the field of Health and Safety of workers therefore brings significant advantages:

- It focuses on compliance with Legislative Decree 81 throughout the company's lifecycle.

- It facilitates compliance and certification with the voluntary standard ISO 45001 (replacing BS OHSAS 18001), specific to the management system for occupational health and safety.

- It helps prevent events (accidents/exposures) that can harm workers.

- It promotes the identification and development of opportunities for continuous improvement of workplaces and equipment/machinery used.

- It supports timely and effective decision-making by carefully examining what can grow the business and what could pose problems for the health and safety of workers.