The origins of the brand

The name Quarta has German origins, in fact it comes from a solution that already existed in the 80s, a solution that dealt with Quality management.

Blulink inherited the name and the solution by deciding to keep the name since the meaning of Quarta comes from the manufacturing field, from the causes or factors that influence a production process, these can be traced back to four macro-groups:

Man

Machine

Materials

Method

Features

Quarta EVO is the software solution to manage and improve the performance of Quality and Safety Management Systems in companies; built on a powerful Workflow engine.

The Quarta suite is simple, fluid and intuitive; able to collect data in real time, analyze them, organize them and automatically create a series of indicators that allow you to keep the entire Quality System under control.

An integrated management of Quality and Safety generates savings in terms of time and costs, more streamlined complaints, easy collaboration with suppliers and measurement of the same.

Quarta EVO allows the management of controls at every stage of the production process: incoming inspection on external supply material and controls following internal processing and on the finished product, with the possibility of acquiring data directly from the measuring machines.

Quarta EVO, with its user authentication and authorization system, fully responds to the new and greater security needs, allowing the suite to open and integrate perfectly with the information systems of stakeholders outside the company (customers, suppliers).

Blulink develops standard solutions starting from innovative development frameworks, with a specific goal: to create the best integrated software solutions for the management of a Quality and Safety System.

More Features

FIGHT THE COSTS

OF NON-QUALITY - COPQ

Quarta EVO software to measure and eliminate non-quality costs is aimed at multiple business sectors, responding to the needs of small and large companies, located all over the world. Its purpose is to reduce costs and minimize risks, supporting companies in improving their flexibility and performance.

Approach

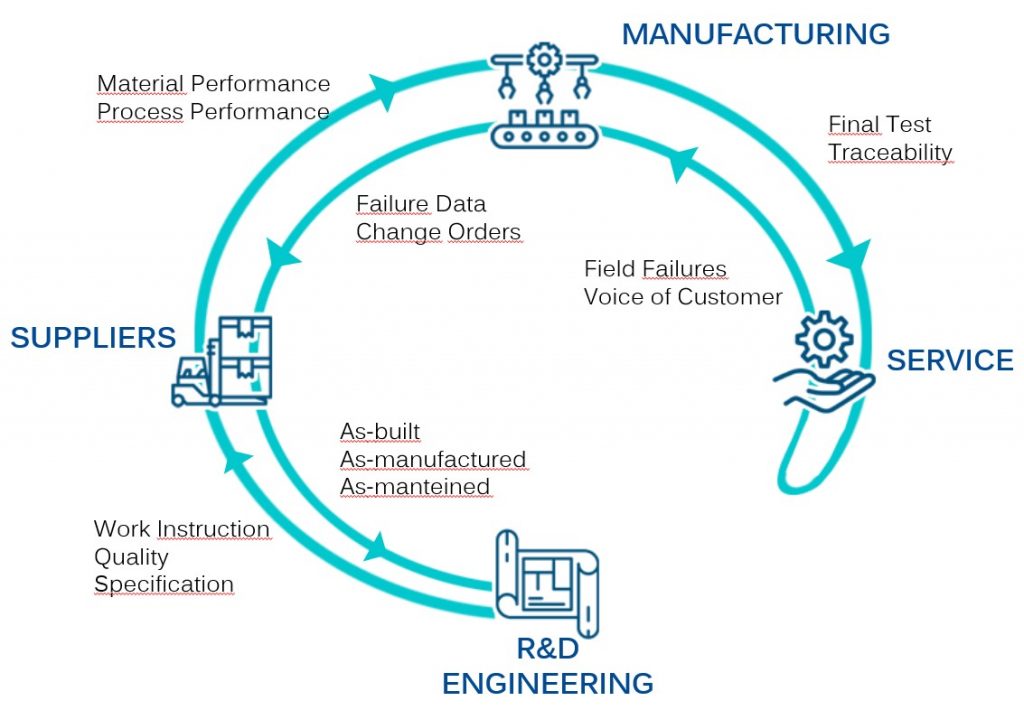

«CLOSED LOOP QUALITY»

Through the management of Closed Loop Quality, it is possible to make all the data that define the quality of the product available to all the corporate bodies involved in a single location.

The goal of Closed Loop Quality management is to improve Quality in advance, involving all company areas in the process.